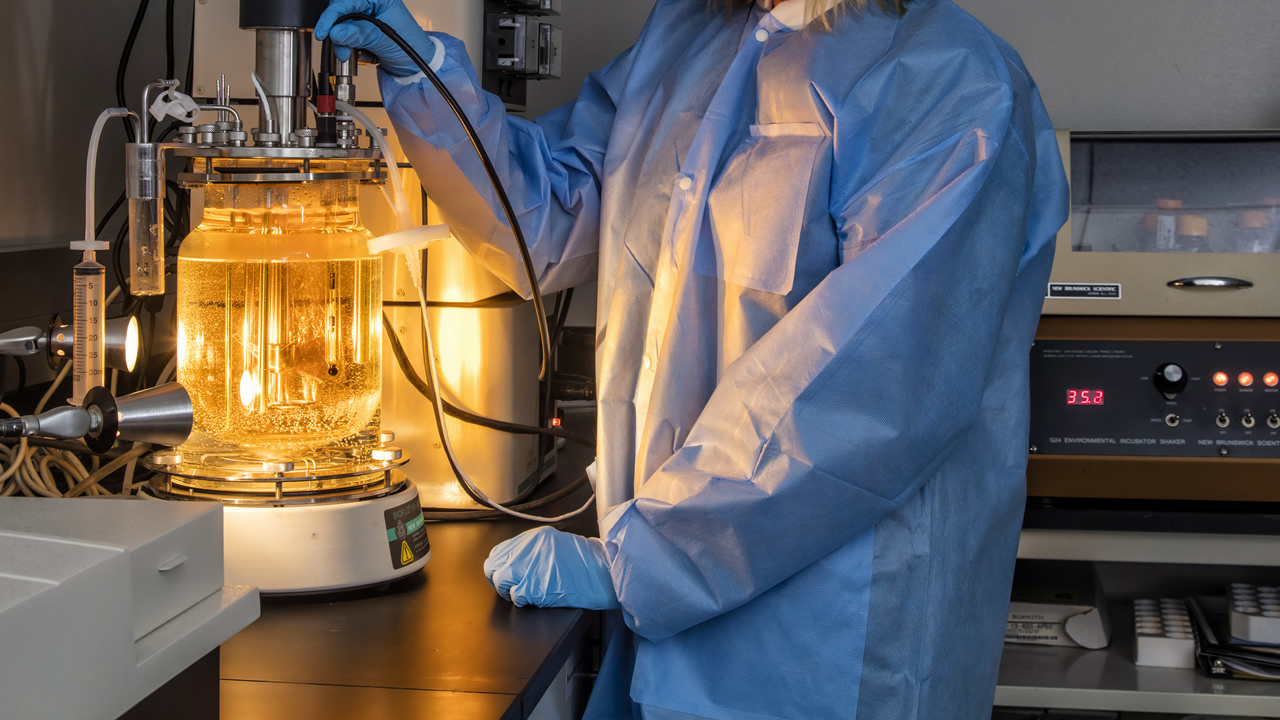

Biopharmaceutical fermentation involves propagating mammalian, yeast, or microbial cells to produce the desired drug product. This process can be used to produce many types of products, including antibiotics, hormones, amino acids or therapeutic proteins. In this course, students will be able to learn the fundamentals of fermentation technology and processes utilized in the chemical

and biotechnology industries. The lab sections will allow the students hands-on experience with a small-scale fermentation process equipment used in the biopharmaceutical industry. Students will also be introduced to the various conditions necessary for sterile media preparation and culture operations.

This course is designed for entry-level bioprocess engineers, technicians and operators, upstream process development scientists and specialists, and incumbent workers. It will also benefit professionals in the biotechnology industry seeking training and hands-on experience in fermentation processes.

- Biomanufacturing process overview

- Overview of cell culture

- Introduction to fermentation processes

- Current Good Manufacturing Practices (CGMP) related to fermentation processes

- Industrial microorganisms and their products

- Phases of cell growth

- Recombinant technology

- Factors that affect cell growth

- Fermentor design requirements

- Parts of fermentor

- Nutritional requirements for aerobic fermentation

- Sterilization principles

- Fermentation instrumentation and controls

- Single-use technologies

- Gain an understanding of the biological principles behind microbial fermentation, growth, and genetic modification.

- Summarize and apply Current Good Manufacturing Practice (CGMP) considerations in fermentation.

- Learn how to optimize growth medium for microbial growth and describe the nutritional requirements for media preparation.

- Describe the basics of fermentor design, instrumentation, and control.

- Identify the components of a small scale fermentor system and gain hands-on experience with operating the system to run a fermentation cycle.

- Demonstrate taking analyte measurements to monitor the growth of cultures.

Delivered in-person in a classroom or lab setting.

Biopharmaceutical fermentation involves propagating mammalian, yeast, or microbial cells to produce the desired drug product. This process can be used to produce many types of products, including antibiotics, hormones, amino acids or therapeutic proteins. In this course, students will be able to learn the fundamentals of fermentation technology and processes utilized in the chemical

and biotechnology industries. The lab sections will allow the students hands-on experience with a small-scale fermentation process equipment used in the biopharmaceutical industry. Students will also be introduced to the various conditions necessary for sterile media preparation and culture operations.

This course is designed for entry-level bioprocess engineers, technicians and operators, upstream process development scientists and specialists, and incumbent workers. It will also benefit professionals in the biotechnology industry seeking training and hands-on experience in fermentation processes.

- Biomanufacturing process overview

- Overview of cell culture

- Introduction to fermentation processes

- Current Good Manufacturing Practices (CGMP) related to fermentation processes

- Industrial microorganisms and their products

- Phases of cell growth

- Recombinant technology

- Factors that affect cell growth

- Fermentor design requirements

- Parts of fermentor

- Nutritional requirements for aerobic fermentation

- Sterilization principles

- Fermentation instrumentation and controls

- Single-use technologies

- Gain an understanding of the biological principles behind microbial fermentation, growth, and genetic modification.

- Summarize and apply Current Good Manufacturing Practice (CGMP) considerations in fermentation.

- Learn how to optimize growth medium for microbial growth and describe the nutritional requirements for media preparation.

- Describe the basics of fermentor design, instrumentation, and control.

- Identify the components of a small scale fermentor system and gain hands-on experience with operating the system to run a fermentation cycle.

- Demonstrate taking analyte measurements to monitor the growth of cultures.